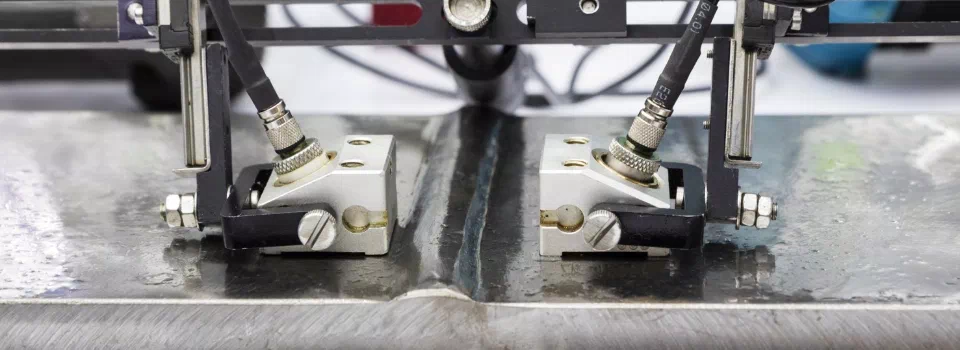

Ultrasonic Testing (UT)

Ultrasonic Testing helps detect inconsistencies within the tested material. Using the UT (Ultrasonic Testing) method, it is possible to identify defects throughout the entire volume of the material. This technique enables the detection of planar defects such as delaminations or cracks. Ultrasonic testing is performed using waves of appropriate wavelength. UT testing is often used as an alternative to radiographic testing. Ultrasonic non-destructive testing has a wide range of applications during the production and operational stages of welded joints, castings, aluminum alloys, and other materials. UT non-destructive testing is most commonly used on components made of steel, aluminum, and their alloys.

UT Testing

We offer a wide range of services related to ultrasonic testing. Our services include both conventional manual UT inspections and semi-automated UT using TOFD (Time of Flight Diffraction) and Phased Array techniques. Our specialists are ready to advise and help you choose the most suitable testing method.

Ultrasonic Testing is known for its exceptional accuracy and speed, and it provides immediate results after inspection. This method is widely used in industries such as power generation, metallurgy, rail, and aerospace. It is particularly effective for inspecting thick and long components and detecting both internal and external defects with high precision.

If you have any questions or concerns, we are here to help.

We invite you to take advantage of our services!

Ultrasonic Device Calibration

Calibration of the ultrasonic device is a crucial step in the ultrasonic testing process. Its purpose is to adapt the device to a specific material and testing conditions to ensure accurate measurement results. Below is a general description of the ultrasonic device calibration process:

-

Selection of a reference sample – first, a reference sample of known thickness is chosen to serve as a calibration standard. This sample should have a homogeneous structure and be representative of the material to be tested.

-

Measurement of ultrasonic wave velocity – next, the velocity of the ultrasonic wave traveling through the reference sample is measured. This value varies depending on the material and is critical for accurate calibration.

-

Setting the echo time – the ultrasonic testing operator configures the time between the emission of the ultrasonic wave and its reflection from the back wall of the reference sample. This is referred to as the two-way transit time.

-

Calibration formula – based on the measured wave velocity and echo time, a calibration formula is established. This formula is used to convert echo times into material thicknesses during actual measurements.

- Verification of results – it is good practice to regularly verify calibration results by comparing measured thicknesses with known values. If necessary, the device settings can be adjusted.