Non-Destructive Testing (NDT)

In our laboratory, we perform various types of non-destructive tests that allow us to detect any irregularities and indicate weak points. They are also referred to as discontinuities (the structure of the material or joint is disturbed). In a case of a weld, such discontinuity is the weakest link and may cause a leak in the installation.

In our laboratory, we perform various types of non-destructive tests that allow us to detect any irregularities and indicate weak points. They are also referred to as discontinuities (the structure of the material or joint is disturbed). In a case of a weld, such discontinuity is the weakest link and may cause a leak in the installation.

The most used method of testing is the radiographic one, because it provides high measurement accuracy and the data are easy to interpret. Ultrasonic testing, magnetic testing, penetrant testing and visual testing are also used to check the quality of welded joints.

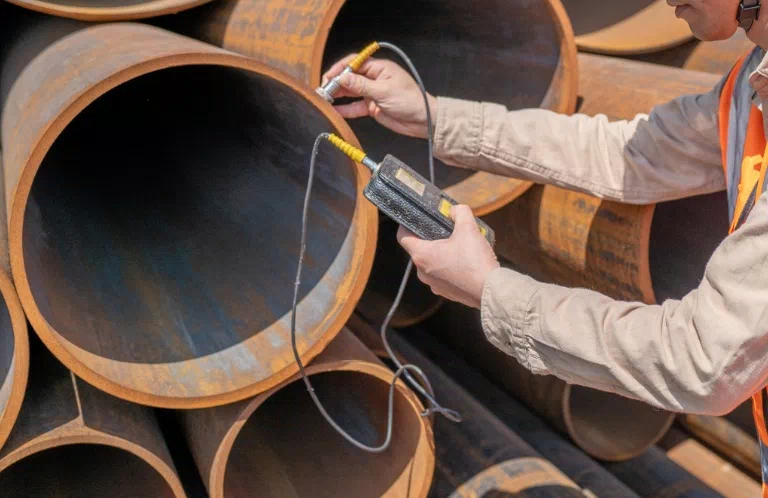

Ultrasonic thickness measurements and others materials testing

Non-Destructive Testing doesn’t affect the structure or physicochemical properties of the material. This group includes radiographic testing (RT), ultrasonic thickness measurement (UTT), ultrasonic testing of weld joints, castings or forgings, as well as visual testing (VT) with or without instruments. Magnetic particle testing (MT) is also used in assessing the surface condition of materials and welds.

Non-Destructive Testing doesn’t affect the structure or physicochemical properties of the material. This group includes radiographic testing (RT), ultrasonic thickness measurement (UTT), ultrasonic testing of weld joints, castings or forgings, as well as visual testing (VT) with or without instruments. Magnetic particle testing (MT) is also used in assessing the surface condition of materials and welds.

Their opposite is for example mechanical hardness measurements during which the material is destroyed. Each of the above methods uses a different type of tool. Radiographic testing involves the use of X-ray or gamma radiation, which when penetrating an object leaves a “trade” on the radiograph of the inconsistencies encountered on its way. In ultrasonic testing we introduce high-frequency waves into the tested material and on the flaw detector screen we observe what happens with this wave. Magnetic particle testing involves observing changes in powder with iron filings under the influence of an induced electromagnetic field. Due to the nature of this field, it is possible to detect indications not only on the surface of the tested element, but also up to about 2 mm below the surface.

In PALAB the research laboratory in Łęczyca near Poznań, we perform the following non-destructive tests and measurements:

- visual testing (VT),

- penetrant testing (PT),

- magnetic particle testing (MT),

- ultrasonic testing (UT),

- radiographic testing (RT),

- macroscopic examination of welded joints,

- ultrasonic thickness testing (UTT),

- bubble-vacuum leak tightness testing (LT),

- hardness measurements with a portable hardness tester (HT),

- tests performed by a mobile radiographic laboratory,

- digitalization (scanning) of radiographs.

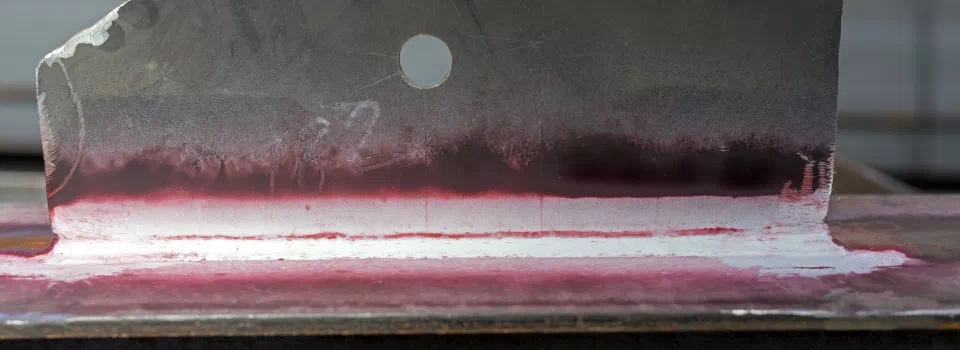

Penetrant testing for material defects

Penetrant testing (PT) is used to assess defects such as rolls, edge bonding, delamination, cracks or non-welds. This is another Non-Destructive Testing method used to evaluate welds. It requires the use of a special coloring agent - penetrant. The evaluation of its decomposition is carried out in UV light or using color technique. Penetrant testing is easy to perform, fast, cheap and effective. However it requires very good surface preparation. It is usually preceded by visual testing.

Non-Destructive Testing (NDT)

Non-Destructive Testing is most often used in the examination of welded joints, castings and forgings. They primarily allow for the detection of material discontinuities. Also thanks to NDT, we can control the product and eliminate any losses and then prevent problems. NDT can be performed at any stage of manufacturing and exploitation. Non-Destructive Testing can confirm the quality of products and that all materials meet all requirements.

Non-Destructive Testing is most often used in the examination of welded joints, castings and forgings. They primarily allow for the detection of material discontinuities. Also thanks to NDT, we can control the product and eliminate any losses and then prevent problems. NDT can be performed at any stage of manufacturing and exploitation. Non-Destructive Testing can confirm the quality of products and that all materials meet all requirements.

In our laboratory we perform a number of non-destructive tests for various industries, including the gas, chemical, petrochemical and construction industries. Our experts have many years of experience and will help you choose the right type of Non-Destructive Testing.

We invite you to take advantage of our offer!