Inspection of Measuring Instruments

Measuring equipment and instruments are only effective when the results they indicate are credible and traceable. For this reason, all measurement and adjustment activities are performed with the highest level of accuracy and in compliance with the procedures of our Management System, certified by DNV to the PN-EN ISO 9001:2015 standard. Verification is carried out in accordance with applicable Polish and international standards, guidelines issued by the Central Office of Measures (GUM), as well as our internal instructions and procedures. Consequently, periodic and professional verification of measuring instruments is essential.

Measuring equipment and instruments are only effective when the results they indicate are credible and traceable. For this reason, all measurement and adjustment activities are performed with the highest level of accuracy and in compliance with the procedures of our Management System, certified by DNV to the PN-EN ISO 9001:2015 standard. Verification is carried out in accordance with applicable Polish and international standards, guidelines issued by the Central Office of Measures (GUM), as well as our internal instructions and procedures. Consequently, periodic and professional verification of measuring instruments is essential.

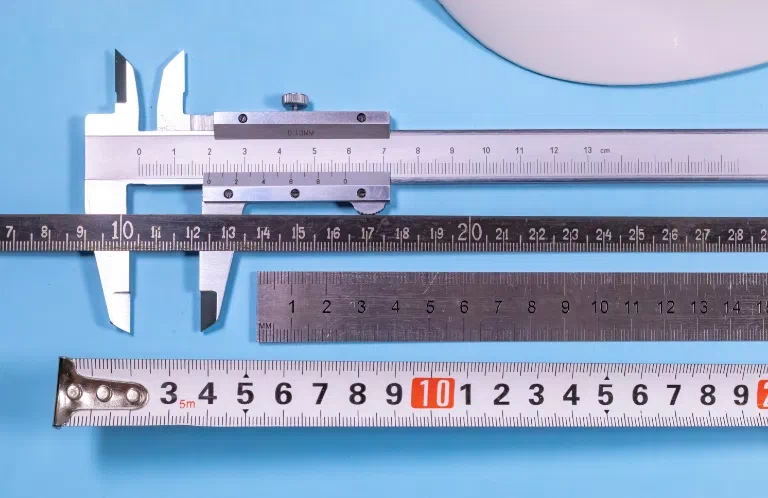

The scope of verification includes:

- gauge blocks,

- calipers,

- micrometers,

- squares,

- protractors,

- gauges and other dimensional measuring instruments,

- workpieces and surface roughness measurements.

Verification of measuring instruments frequently reveals various nonconformities. Therefore, we additionally carry out minor repairs and adjustments of instruments when required.

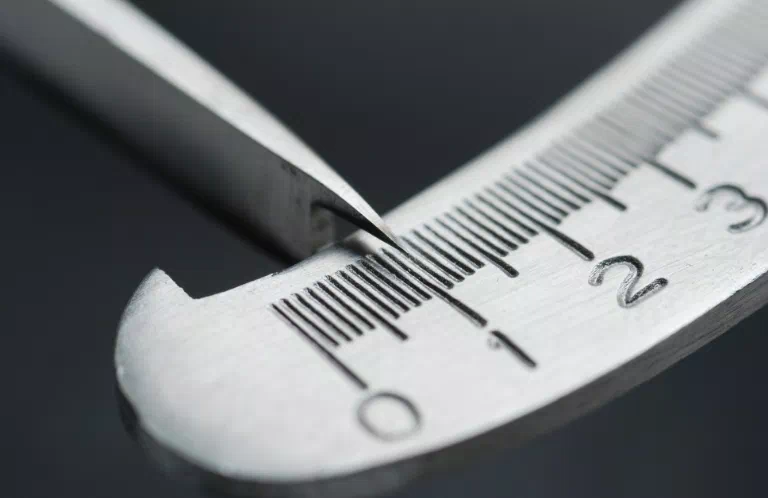

Measurement Standards – Definition and Significance

Measurement standards are instruments with confirmed and exceptionally high accuracy, intended to ensure metrological traceability by comparison with the results of other measuring devices. They constitute a fundamental element of the calibration process, enabling the identification of measurement errors and the adjustment of accuracy of subordinate instruments. The application of measurement standards ensures that the measuring equipment used provides reliable, repeatable and precise results, which is critical across scientific, industrial and other domains where measurement accuracy and traceability are of key importance.

Measurement standards are instruments with confirmed and exceptionally high accuracy, intended to ensure metrological traceability by comparison with the results of other measuring devices. They constitute a fundamental element of the calibration process, enabling the identification of measurement errors and the adjustment of accuracy of subordinate instruments. The application of measurement standards ensures that the measuring equipment used provides reliable, repeatable and precise results, which is critical across scientific, industrial and other domains where measurement accuracy and traceability are of key importance.