Microscopic Testing

Our company specializes in comprehensive microscopic examinations of steels, cast irons, and non-ferrous metals. Thanks to advanced research equipment and the experience of our team, we are able to provide you with precise and reliable results that support a deeper understanding of the structure and properties of various materials.

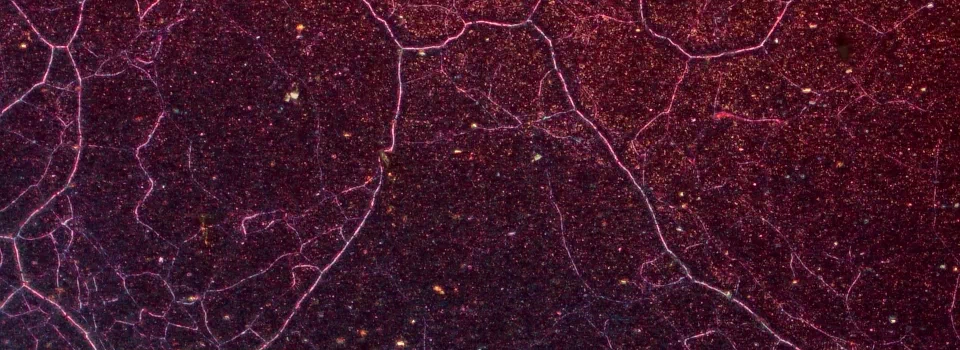

Metallographic Examinations

Metallographic examinations are an indispensable tool for industry, science, and other sectors where understanding the microstructure of metallic materials is of key importance. Using an optical microscope with a maximum magnification of 1000x and modern imaging techniques, we can evaluate the structures of examined samples with high precision.

How does the microscopic analysis process work?

The testing process begins with sample preparation, which involves cutting, grinding, polishing, and etching. Careful sample preparation - properly adjusted to the specific material - is crucial for obtaining reliable results.

Microscopic examinations result in comprehensive reports containing descriptions and images of the observed microstructures, along with expert opinions and interpretations when required. This information is invaluable for design, production, and quality control processes. It helps in making informed decisions about materials and their treatment, leading to savings in both time and resources.

Microscopic examinations performed at the PALAB Laboratory include, among others:

- Microstructure analysis – observation of steel, cast iron, and non-ferrous metal structures.

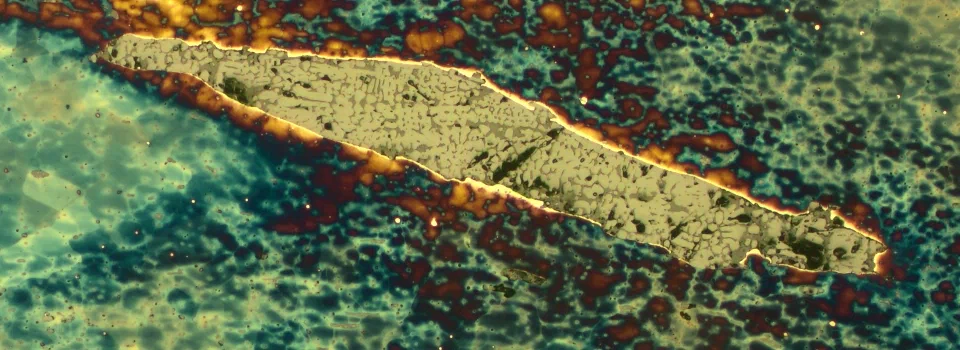

- Measurement of coating and surface layer thickness – observation of metallic coatings on various alloys as well as carburized and nitrided layers on steel.

- Microscopic observations aimed at determining the causes of damage in metallic components.