Analysis of Causes of Damage in Metallic Components

We invite you to take advantage of our microscopic examination services, which also include the analysis of damage causes in metallic components. Our company has an experienced team of metallography experts who use advanced microscopic techniques to analyze and identify the causes of metal failures. Thanks to our research, clients gain valuable insights into materials, products, and processes - enabling them to make informed decisions that improve quality and production efficiency.

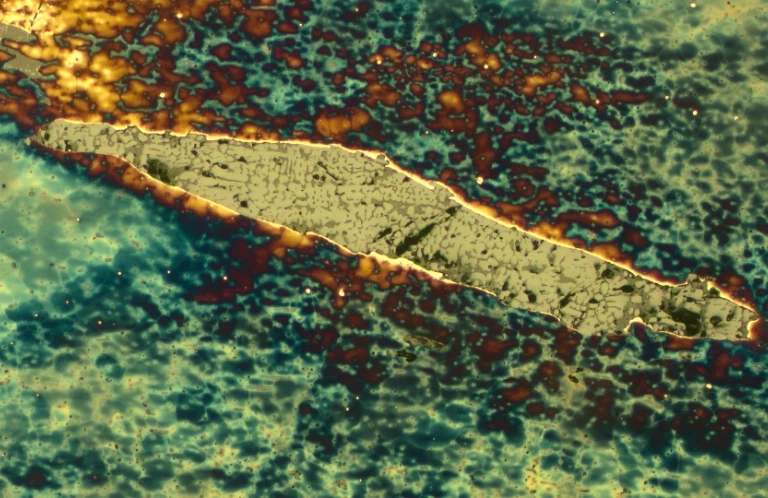

Metal Microstructure

Microscopic examinations allow for an in-depth analysis of the microstructure of metals, which is key to understanding the causes of damage. Our optical microscope enables detailed observation of material structures and identification of various types of defects, such as: cracks occurring during manufacturing or operation, non-metallic inclusions in metallurgical products, welding imperfections in test joints, improper structural components in cast iron materials. In some cases, the observed damage allows for the identification of its potential origin, such as material fatigue, corrosion, deformation, excessive loading, or inadequate process parameters. This helps our clients locate the source of the problem and implement effective corrective actions.