Competences

Many small and large companies have placed their trust in us. The quality of our services, along with our precision and continuous pursuit of perfection, enables us to handle both small and large projects while maintaining convenient lead Times.

Construction of the LNG Terminal in Świnoujście

We provided comprehensive support for the construction project in the field of non-destructive testing, including visual, penetrant, radiographic examinations, as well as ferrite content measurements. Total number of welds tested: over 6,000.

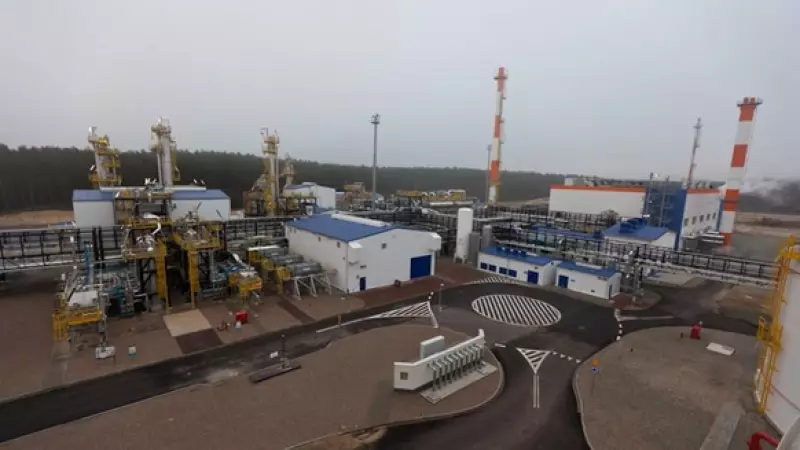

Expansion of the Goleniów, Odolanów and Gustorzyn Gas Compressor Stations as part of the BALTIC PIPE project

Depending on the location, we either provided a comprehensive service or offered support in non-destructive and destructive testing for the newly constructed installations. In total, we tested over 10,000 welded joints.

Expansion of the Oil Terminal in the Port of Gdańsk — a project under PERN’s Megainvestment Programme

We inspected several thousand linear meters of welded joints during the construction of three storage tanks with a capacity of 100,000 m³ each, as well as two tanks with a capacity of 45,000 m³.

Sątopy – Grodzisk Wielkopolski Gas Pipeline

We carried out a full scope of non-destructive and mechanical testing for the construction of a 22 km long DN300 high-pressure gas pipeline.

Johan Sverdrup Field in the North Sea

Several hundred meters of welded joints were inspected using VT, UT, PT, and MT methods during the production of seven cranes for the newly built platform.

Mercedes-Benz – Engine Factory in Jawor

Non-destructive testing (VT, RT, MT, PT and UT) of several hundred welded joints during the production of pipelines for the newly constructed factory.

Hydraulic Accumulators

We performed VT, UT and MT testing on over 300 hydraulic accumulators to detect and locate discontinuities that developed during operation.

Wind Turbine Tower Components

VT and PT testing of aluminium wind turbine tower components installed in various locations around the world.

Repairs and Construction of Boilers in Conventional Power Engineering

Comprehensive non-destructive testing performed during the overhaul and modernization of water and steam boilers. The testing is carried out as part of the commissioning of new installations. We also perform testing related to the diagnostics of installations during their operational lifespan.

Left-Bank Wastewater Treatment Plant in Poznań

In December 2009, we completed testing works for the construction of the Left-Bank Wastewater Treatment Plant in Poznań. Throughout the construction period, we served as the main contractor for radiographic testing.

Municipal Stadium in Poznań

In March 2010, we completed the coordination and execution of all non-destructive testing required for the installation of the two largest roof structure girders at the Municipal Stadium in Poznań (this included UT testing of approximately 1,800 meters of welded joints and MT testing of approximately 3,200 meters of welded joints).

Underground Gas Storage Facility in Wierzchowice

In 2011, we carried out radiographic testing as a subcontractor for the construction of the Underground Gas Storage Facility in Wierzchowice. We inspected over 800 welded joints.

Poznań Main Railway Station

In 2012, we performed ultrasonic and magnetic particle testing of the steel roof structure during the construction of the Poznań Main Railway Station.

Marshal’s Office Building in Poznań

In 2012, we carried out ultrasonic and magnetic particle testing of the steel structure during the construction of the new Marshal’s Office building in Poznań.

ORLEN Refinery in Płock

In 2012, we performed pipeline thickness measurements at the ORLEN refinery in Płock. Over 25,000 measurement points were inspected.

Siemens AG

In 2012 and 2013, we served as the main contractor for non-destructive testing during the inspection of all Siemens AG tram units operating in Poznań. Our cooperation in this area with Siemens Sp. z o.o., Infrastructure & Cities Sector, continues to this day.

Thyssen Krupp Uhde High Pressure Technology

High-pressure process installations at the Imperial Tobacco facility. We served as the main contractor for radiographic testing for ThyssenKrupp Uhde High Pressure Technology. Over 1,000 welded joints were inspected.

SOLARIS

We carried out non-destructive testing during the production of bogies for SOLARIS trams. The testing covered the Poznań, Braunschweig and Olsztyn contracts.

EDF Kraków

Complete non-destructive testing during the major repair of the boiler at the EDF Kraków CHP plant.

Using ultrasonic testing, we examined over 4,500 welded joints.

Petrofac Services Ltd.

Platform refurbishment project for Petrofac Services Ltd. We performed non-destructive testing using VT, PT, MT and RT methods during the construction of offshore installations for Gdańsk Shiprepair Yard “Remontowa” S.A. Over 2,700 welded joints were inspected.

Opole Power Plant

Construction of new power units at the Opole Power Plant.

PT, MT, RT and UT testing performed during works related to the construction of rotary air preheaters.

Gajewo and Brońsko Oil Fields

PT, MT, RT and UT testing carried out during works related to the development of the Gajewo and Brońsko oil fields. The anticipated number of welded joints to be inspected is 2,000.