Mechanical Testing

At the PALAB Laboratory, we specialize in performing mechanical tests of welded joints as well as metals and their alloys. The results obtained from these tests facilitate the proper selection of welding parameters and allow the tested components to be used within permissible load limits. We carry out tests aimed at qualifying welding technologies, certifying welders, and recertifying metallurgical products such as plates, bars, sections, profiles, and pipes. We have a comprehensive range of machinery, ensuring full self-sufficiency in the preparation of test samples.

At the PALAB Laboratory, we specialize in performing mechanical tests of welded joints as well as metals and their alloys. The results obtained from these tests facilitate the proper selection of welding parameters and allow the tested components to be used within permissible load limits. We carry out tests aimed at qualifying welding technologies, certifying welders, and recertifying metallurgical products such as plates, bars, sections, profiles, and pipes. We have a comprehensive range of machinery, ensuring full self-sufficiency in the preparation of test samples.

Mechanical Testing Methods

Mechanical testing plays a crucial role in various fields such as industry, science, engineering, medicine, construction, and many others. The methods used at the PALAB Laboratory include:

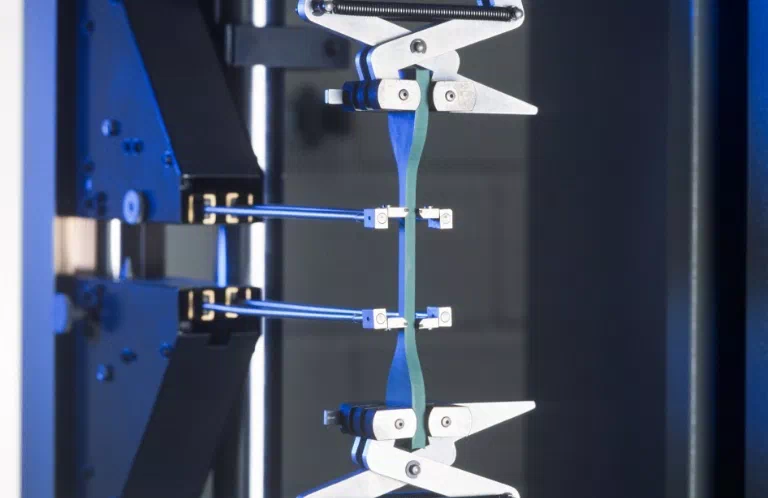

- Tensile test – determines the material’s strength under tensile forces. It allows the strength characteristics of the tested alloy or joint to be identified and presented in the form of a graph.

- Impact test – determines the material’s resistance to dynamic loads at a given temperature. This is a critical parameter for components that may be exposed to impact.

- Bend test – determines the ductility of metals and their ability to undergo plastic deformation under bending. It helps reveal potential discontinuities in welded joints.

- Fracture test – evaluates the fracture surface of a joint for welding imperfections such as cracks, porosity and blowholes, inclusions, lack of fusion, or incomplete penetration.

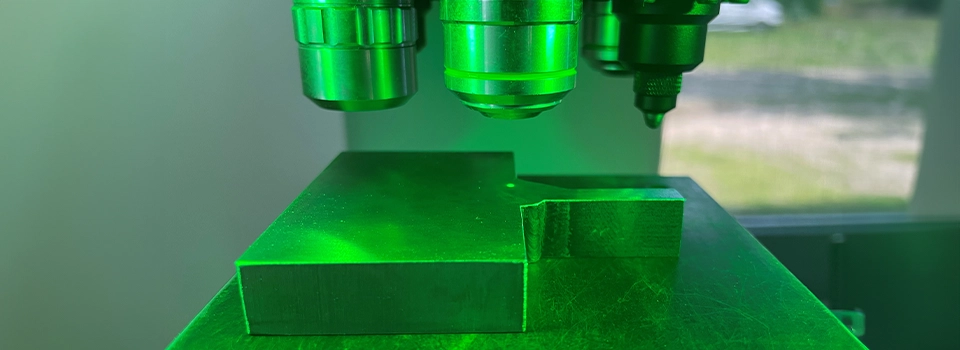

- Hardness testing – determines the material’s resistance to deformation caused by a concentrated load applied by an indenter. Hardness testing helps assess the material’s durability.

- Microhardness testing – provides precise measurement of surface hardness, thin coatings, and surface layers using a small load.